Australian Made

Jewellery that is ethically made from sustainably sourced metals and materials, by skilled jewellers working for fair wages in a safe and comfortable work environment.

How it’s Made

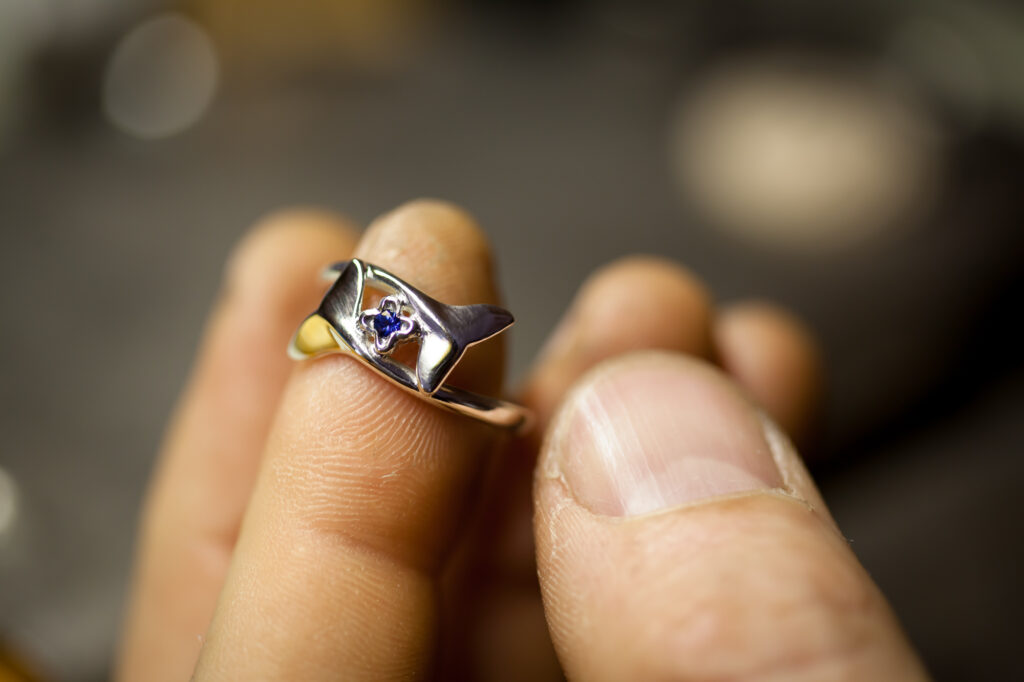

What do we mean when we say our jewellery is “handcrafted”? Hand-carving every single piece of jewellery would be time-consuming and extremely expensive for you, the customer. Instead, we use an ancient jewellery-making technique called the the lost-wax casting method. Since all of our designs are completely original, the design process usually starts off with a hand-drawn sketch. Once we’ve nailed down the basic design, we create a sculpture of that design by carving it out of wax or metal. This carving may go through several rounds of revisions and tweaking until it until we get it perfect – the result is called the “master”. More recently we have also started using CAD (computer aided design) programs to illustrate the design and create a 3D print, which is then perfected and finished off by our jewellers.

From the “master” we create a mould. The mould is used to create multiple wax replicas of the original, which are then cast into the desired metal. To ensure our jewellery is of the highest quality, we have partnered with a reputable casting house here in Australia that specialises in this process. Our jewellers then assemble, set gemstones and hand-polish each piece right here in our Hervey Bay workshop. Finally, every piece goes through our rigorous quality-control to ensure you receive a beautiful keepsake, guaranteed to last forever.

In addition to casting, we utilize many traditional handmade jewellery techniques when doing custom designs, refurbishments and repairs. Our jewellers our fully qualified in the art of a traditional “handmake”, where every component of a piece of jewellery is made by hand – from the initial hand-drawn sketch, to rolling out the metal, fabricating the ring, and setting the final gemstones. We have recently invested in a state-of-the-art workshop with the latest technology and tools, to ensure our jewellers have every opportunity to hone their skills and produce high-quality work. A new laser welder and diamond setting microscopes allow our jewellers to work better and more efficiently, and have greatly improved the quality and precision of our gem setting work.

Why it Matters

The trend of buying and selling products made cheaply overseas, particularly in the jewellery industry, has spiked considerably in recent years. You’ve heard of “fast fashion”, well “fast jewellery” is no different. The majority of jewellery made today is mass-produced in large factories with poor working conditions and little regard for environmental impact. Not to mention, the jewellery is often made cheaply from lower quality materials, meaning it ends up breaking or wearing out, and getting thrown away and replaced without a second thought. This cycle is devastating for the environment, and ultimately costs you more in the long run. Our philosophy? “Buy well, buy once.” It saves you money, and it helps save the planet.

Because we make everything ourselves, we can guarantee the quality and workmanship of our jewellery. You can also sleep easy knowing your jewellery is ethically made from sustainably sourced metals and materials, by skilled jewellers working for fair wages in a safe and comfortable work environment. We might be a small business but we consider ourselves a leader in the industry when it comes to making ethical and sustainable jewellery. By choosing to make all of our own jewellery right here in Australia and partnering with Australian suppliers whenever possible, we are contributing to an industry that would otherwise be lost to overseas competition. By employing and training local jewellers, we are also helping to maintain a qualified workforce that can continue to train the next generation. And because our jewellery is guaranteed to last – literally forever – we aim to bring back the standard of what quality jewellery really means.